There’s no such thing as “too efficient”. There’s always room for improvement. It’s why businesses are forever under pressure to deliver on new operational efficiencies whether through reducing costs or improving outputs. But what happens when you genuinely feel you’ve exhausted every avenue and turned over every stone you can within the organisation? Simple. You do as Harley Davidson did, and look beyond your organisation…

A solution stronger than steel

In June 2018, the EU imposed tariffs on a raft of US-made goods following duties the White House had placed on imported steel and aluminium. For Harley Davidson, tariffs on their bikes soared from 6% to 31%, set to rise further in 2021.

This sent their materials costs through the roof, which meant they needed to increase their prices, in-turn making them seriously uncompetitive in the market. But customers aren’t going to pay more for what they’ve always had. So, the motorbike brand needed to find a way to cut costs.

From their point of view, they were already working as efficiently as they could be. Their next option would have been to insist suppliers cut their costs if they wanted to keep doing business with them. But even if their suppliers agreed, it wouldn’t have had a big enough impact for Harley Davidson to keep their costs competitive for customers.

So, they turned the usual narrative on its head, and did something unusually brilliant. They asked their suppliers to tell them how Harley Davidson could operate more efficiently. And the insight and ideas the suppliers provided was invaluable. They saw things that only an external eye looking in could see – huge inefficiencies in the way they were interacting and transacting with themselves as a supplier, as well as ways they were running general business operations.

As a result, Harley Davidson identified a whole host of ways to improve their operational efficiency and overcome the challenges caused by the steel tariff. But how does their story help you?

A Harley Davidson-inspired Sprint

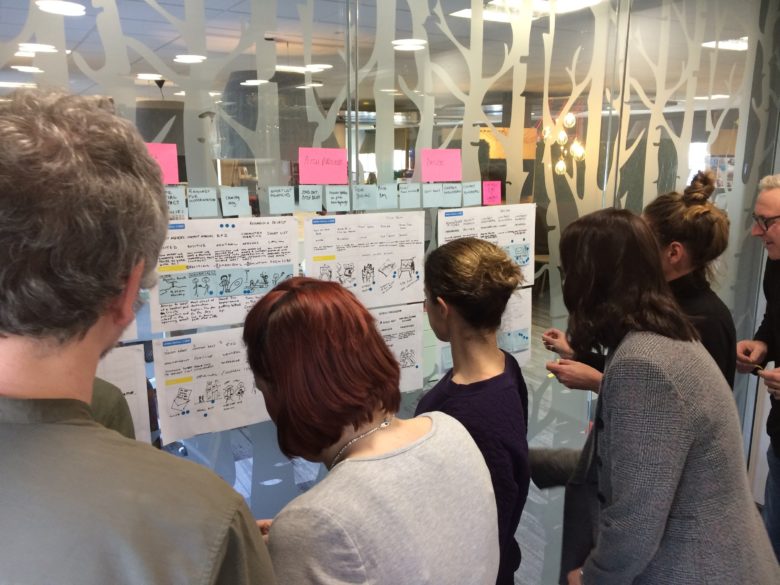

In short, Harley Davidson used co-creation with their supply chain to find new ways to operate more efficiently. Which is something you can easily explore too. Using a Sprint format where you bring suppliers and people within your organisation together in a room for a day, you can rapidly capitalise on their fresh perspective to identify opportunities, come up with new ideas and problem-solve operational issues. By looking at internal problems from an external point of view, you’ll uncover things you’re not seeing and won’t be blinkered by one dimensional outcomes such as the easiest way to cut costs.

A Sprint style co-creation session with your suppliers is a fast and condensed way of doing exactly as Harley Davidson did. And they’re not the only ones exploring this new approach…

Food for thought

When Premier Foods brought its marketing team and people within its supply chain together, they came up with a ready-to-eat version of their sachet mousse dessert, Angel Delight. Together, they had an idea, identified the technology needed to make it work, and got buy-in at an operational and supply level. Working co-creatively is also what lead to Premier Foods developing a convenient pot snack version of its Pasta ‘n’ Sauce product in just seven months. For this organisation, co-creation helps generate innovative ideas, increases the speed to market and remove waste from the supply chain, meaning funds can be reinvested elsewhere.

If you’re faced with the challenge of finding new ways to improve efficiencies, you won’t get anywhere new by going down the same paths. Being too close to something can hinder any chance of new ideas. It’s time to look beyond the four walls of your business and invite others to look in and show you what you’re missing.

Interested to learn how you could use a Sprint to unlock value from suppliers? Get in touch at [email protected] and we can help you meet a specialist.