Millions of workers across the globe have suddenly transitioned to working from home. There are many practical and physiological challenges to this abrupt change, so give yourself a break if everything hasn’t been smooth sailing.

Millions of workers across the globe have suddenly transitioned to working from home. There are many practical and physiological challenges to this abrupt change, so give yourself a break if everything hasn’t been smooth sailing.

Fortunately, the continuous improvement principles that help us be efficient in the office apply in much the same way at home. The eight wastes of Lean, for example, create friction and lower productivity for remote workers as much as they do on a factory floor.

Here are some ideas for spotting and eliminating them while working from home.

Inventory

The waste of inventory is related to the excess production and storage of items that are not needed at this time. You probably don’t have a garage full of products waiting to be shipped to customers, but you might find the waste of inventory if you think about it differently.

At home, excess inventory may be a pile of documents that you don’t need to work on right now or boxes of office supplies that just gather dust. It might mean applications on your desktop that you never use or old files that could be archived. Think about improving your efficiency by getting rid of physical and electronic “stuff” that you don’t really need.

Over-Processing

Over-processing refers to work that is not strictly necessary and doesn’t provide additional value. In a factory, this might mean adding features to products that customers don’t use or want. When working from home, over-processing might take the form of layers of approval for minor decisions, or perfunctory reports.

A common problem that remote workers face is the need to enter the same data into multiple systems. This is a classic case of over-processing that can often be addressed with systems integration.

Movement

In an office or factory, the waste of movement happens when people must go from one place to another to get needed items or preform process operations. This can occur at home as well if your workspace isn’t well-appointed.

Do you have the things you need at hand in the space where you will be working? Are your phone and charger located nearby? Is equipment that you share with others, like printers situated in an easily accessible space? Depending on the size of your house, you might want to consider getting a small water cooler or coffee machine for your workspace to eliminate unnecessary trips to the kitchen.

Transportation

While the waste of movement involves the unnecessary motion of people, the waste of transportation addresses the unneeded movement of things. When everyone is working from home, the biggest cause of the waste of transportation is usually email.

Documents get sent from one computer to another, creating duplicate files and a dubious chain of custody. This problem can be significantly reduced with the use of shared files, such as Google Docs. It is also helpful to store documents directly in the system that is used for improvement management rather than sending them to and from individual users inboxes.

Waiting

The waste of waiting occurs whenever a process is waiting for inputs or information from another source. It can take the form of waiting for decisions, approvals, or work from a peer. The usual flow of information and work that you experience in the office is probably quite different than what you experience working from home.

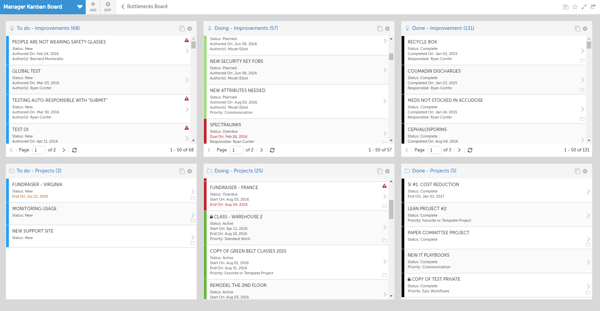

To reduce the waste of waiting, it is a good idea to schedule planned check-in times between supervisors and team members. Be sure that all tasks have due dates and milestones assigned. Improvement management software with alerts and notifications is a big help. Electronic Kanban boards are also an effective way to visualize work and avoid both waiting and backlogs.

Overproduction

Overproduction happens when too much of something is produced. It is a problem because it leads to the wastes of inventory and transportation. In a remote working environment, overproduction often takes the form of too many meetings (calls), meetings that last longer than necessary, or the wrong people in meetings.

While communication is crucial when everyone is distributed, too much of a good thing is a productivity drain. Think about the most effective method of communication.

Defects

It is easy to understand defects in terms of the production of widgets, but defects take many forms. For information workers, defects can be bad data entry, spreadsheets that contain errors, software errors, and information that isn’t effectively communicated or well understood.

It pays to be especially aware of the potential for defects if you’ve unexpectedly become a remote worker. It might be wise to add a further peer review for vital work product. It is also smart to avoid multi-tasking and minimize interruptions.

Human Potential

Perhaps the most significant risk of waste for remote workers is the waste of human potential. Personal and professional development might not be at the top of the list right now, but they should not be ignored. Leaders should help employees find ways to continue to learn and develop new skills. Team members should proactively seek out opportunities for growth. Many organizations and educational institutions are offering online classes that can help break up the boredom of social distancing.

We hope that this post has given you some food for thought and ideas on how to spot the eight wastes of Lean in your own home office. If you have other examples, we’d love to read about them in the comments.

![[Watch Now] How to Leverage Lean for Long-Term Success](https://no-cache.hubspot.com/cta/default/326641/eb5ac7b8-b040-48b7-810e-1589561ffff9.png)

Add a Comment